Continuously operating sludge system

The purpose of the sludge system is to continuously remove the sludge which, together with water, is pumped for this and which flows into the tub itself.

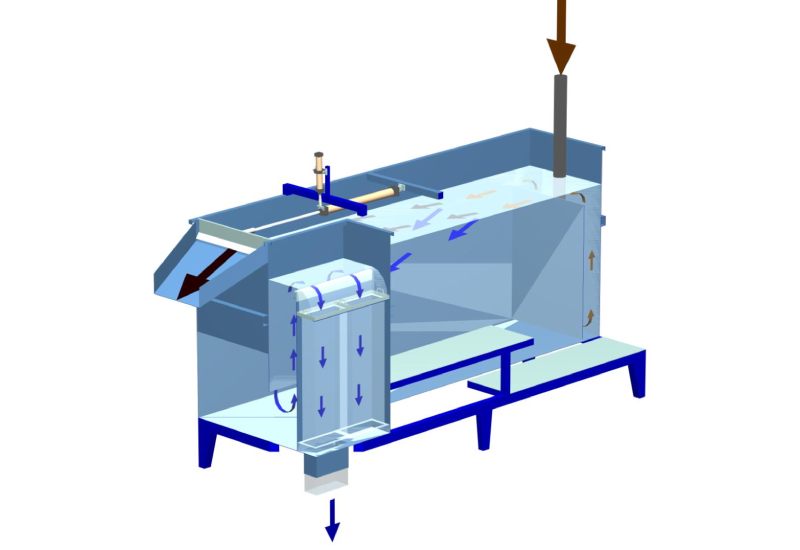

The sludge plant receives process water after completion of the painting process, which with a self-priming pump leads the water into the first room of the tank. In this space, the water momentarily gets more space, whereby the speed of the water decreases. The room in which the water is supplied is provided with an assault, which via this brings the water to the next basin, where the speed of the water again decreases. During these speed changes, the salmon sludge is allowed to develop into flocks and rise into the air in the tank before it is slowly transported towards the chute. Here the paint sludge is scraped away from the water and falls into a sludge bag/jute bag.

The scraping itself takes place with a pneumatic unit, which is controlled by two cylinders, moves the scraper itself in a cycle, so that the scraper is partly in the water and partly moves up the slide pushing the sludge in front of it.

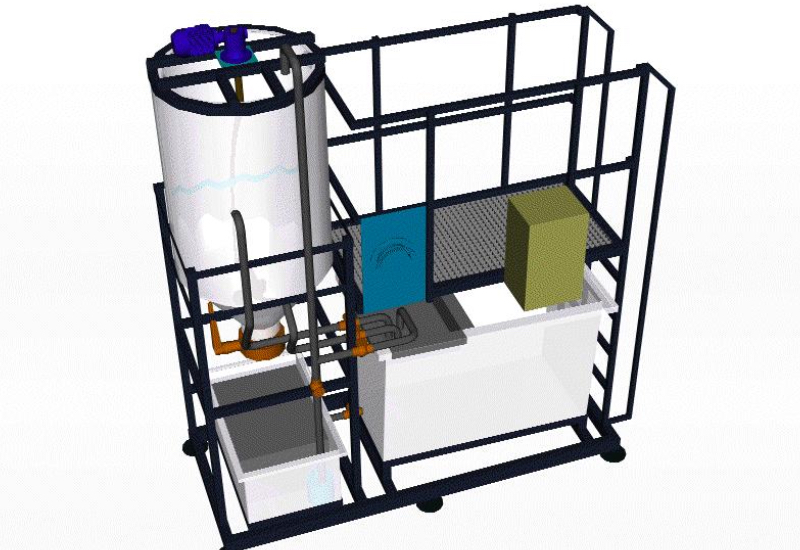

The automatic and cycle of the scraper is controlled by the automatic switchboard, which works purely pneumatically and otherwise contains a timer that also works completely pneumatically. This minimizes risks when working in classified zones.